Paint defects: What is water spotting, what causes water spotting and how can the risk of water spotting be minimised?

What is water spotting when it comes to working with industrial coatings and how is it caused?

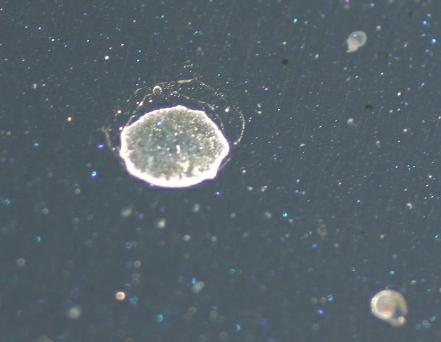

Water spotting occurs when dried mineral deposits are left on a surface after being allowed to air dry.

These light, whitish circular spots, which can either swell or indent the surface of the coating affecting the aesthetic of the finish.

Water spotting is a visual flaw that results from water being present on a surface due to be painted, or on the actual paint itself. This flaw can manifest as hazy marks, circles or matte patches.

Water spotting is typically due to the paint’s vulnerability to water especially when elements dissolved in water settle on the paint layer as the water dries up.

Even though water marks are more noticeable on shiny finishes, the issue can also originate from the sedimentation of contaminants on the freshly painted surface or on the underlying primer layer.

This susceptibility to water might be a result of inadequate curing, the presence of water-attracting solvents, amines, or other polar materials in the layer and so forth.

Salts, acids or other materials gathered on or washed away from the layer can influence the paint’s curing process, leading to curing difficulties or affecting the adhesion of subsequent layers.

How can you avoid water spotting when working with industrial coatings?

The severity of water spotting is dependent on the exposure time to moisture and the freshness of the finish. It can range from mild (recoverable when dry) to severe (requiring a complete re-coating).

Here are some ways to avoid water spotting when working with industrial coatings.

Guard against applying paint too thickly. If you’re using a thinner, make sure it is suitable for the topcoat and the surface and use. If you’re using hardener, ensure you use the most appropriate one and at the correct mixing ratio. And give your topcoat the right amount of time to cure.

Follow application recommendations on manufacturer technical data sheets.

Ensure that your spray gun is in good working order. Finally warm the object and material up to a room temperature of 20 °C/68°.

How can you rectify water spotting when working with industrial coatings?

The first thing to do is always contact the paint manufacturer before commencing rework. They will always have the best advice and will know how they’re products can tackle the problem.

In terms of rectification, the first thing to do after curing is to wash the surface with clean water and wipe it down with a dry cloth to see if it removes the spotting. If the spotting is still present after thorough-drying, water spotting marks can be removed with careful polishing.

If they remain visible after this, the best approach is to sand and repaint the dry surface.

For more technical advice on working with industrial coatings, click here.